Home

Experimental Archaeology

Part of an early blast furnace (Araglin, Ireland)

Conferences

Contents of one box in the National Slag Collection

Documentary record search

Highly vesicular bloomery slag

More comparative studies

Artefactual evidence

Just digging

Experimental reconstruction

Recording artefacts in situ

Open cast iron ore mining, Romano-British

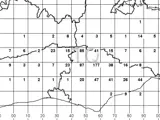

Activity frequency mapping (iron works)

Comparing excavated sites

Crafts

Outcrop of sideritic ore overhanging sandstone

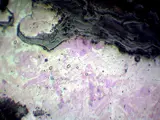

Etched sample of unworked bloomery iron (photomicrograph)