Home

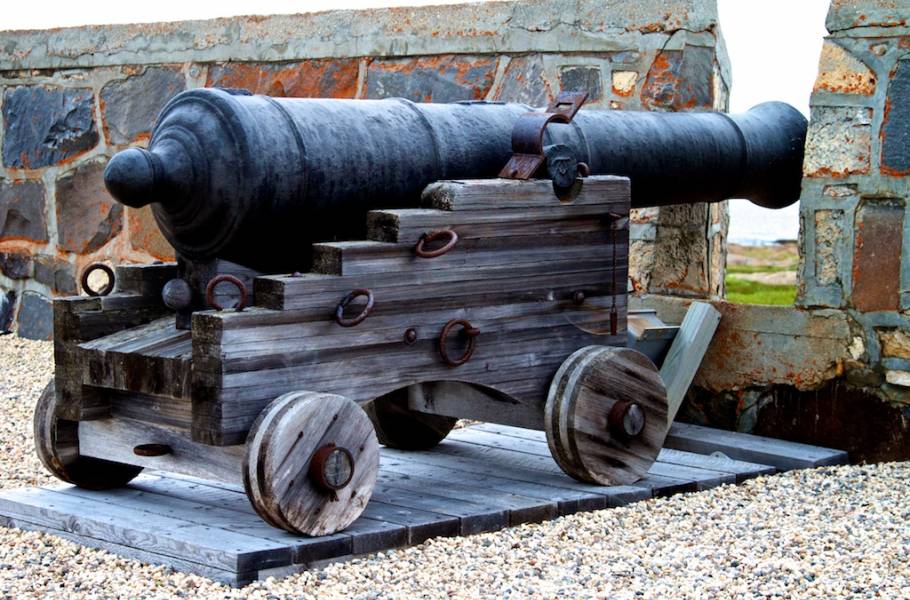

Part of an early blast furnace (Araglin, Ireland)

artefactual evidence

Highly vesicular bloomery slag

Contents of one box in the National Slag Collection

experimental archaeology

& just digging

Etched sample of unworked bloomery iron (photomicrograph)

Open cast iron ore mining, Romano-British

comparing excavated sites

experimental reconstruction

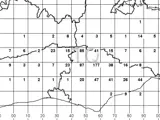

Activity frequency mapping (iron works)

Crafts

Documentary record search

Conferences

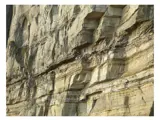

Outcrop of sideritic ore overhanging sandstone

more comparative studies