Eleanor Blakelock describes the results of a comparison between urban and rural Anglo-Saxon iron knives

Knives are particularly useful for archaeometallurgy studies because they are present in a range of archaeological contexts, are composite artefacts using more than one type of iron alloy and can provide a wealth of technological data. My undergraduate research has shown that there appear to be dramatic differences between the manufacturing methods and quality of metals used in settlements and cemeteries (both urban and rural), and also changes in manufacture techniques over time. In addition the review paper demonstrated the paucity of archaeometallurgical investigations of this vital commodity and the importance of reviewing and re-assessing past studies, in light of new research.

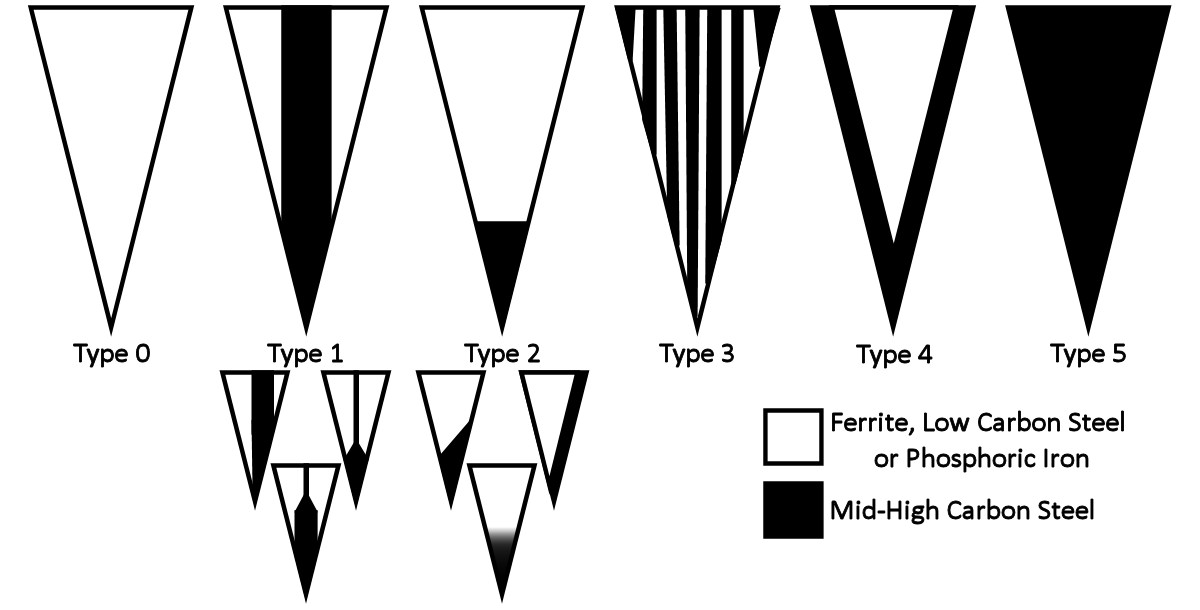

In the past archaeometallurgical studies carried out in the 1980s and 1990s of iron knives have taken much from archaeology but have given little in return. Therefore the main aim of the PhD research was to collate these studies and to increase the sample size, by adding knives from new sites which have been neglected by past studies. Knives from these sites were selected based on non destructive x-radiograph analysis and then sections taken for both metallography and chemical analysis. The data was then used in conjunction with the Early Medieval archaeological record to answer questions about standardisation, specialisation, skill of the smithy, scale of manufacture and distribution of iron artefacts.

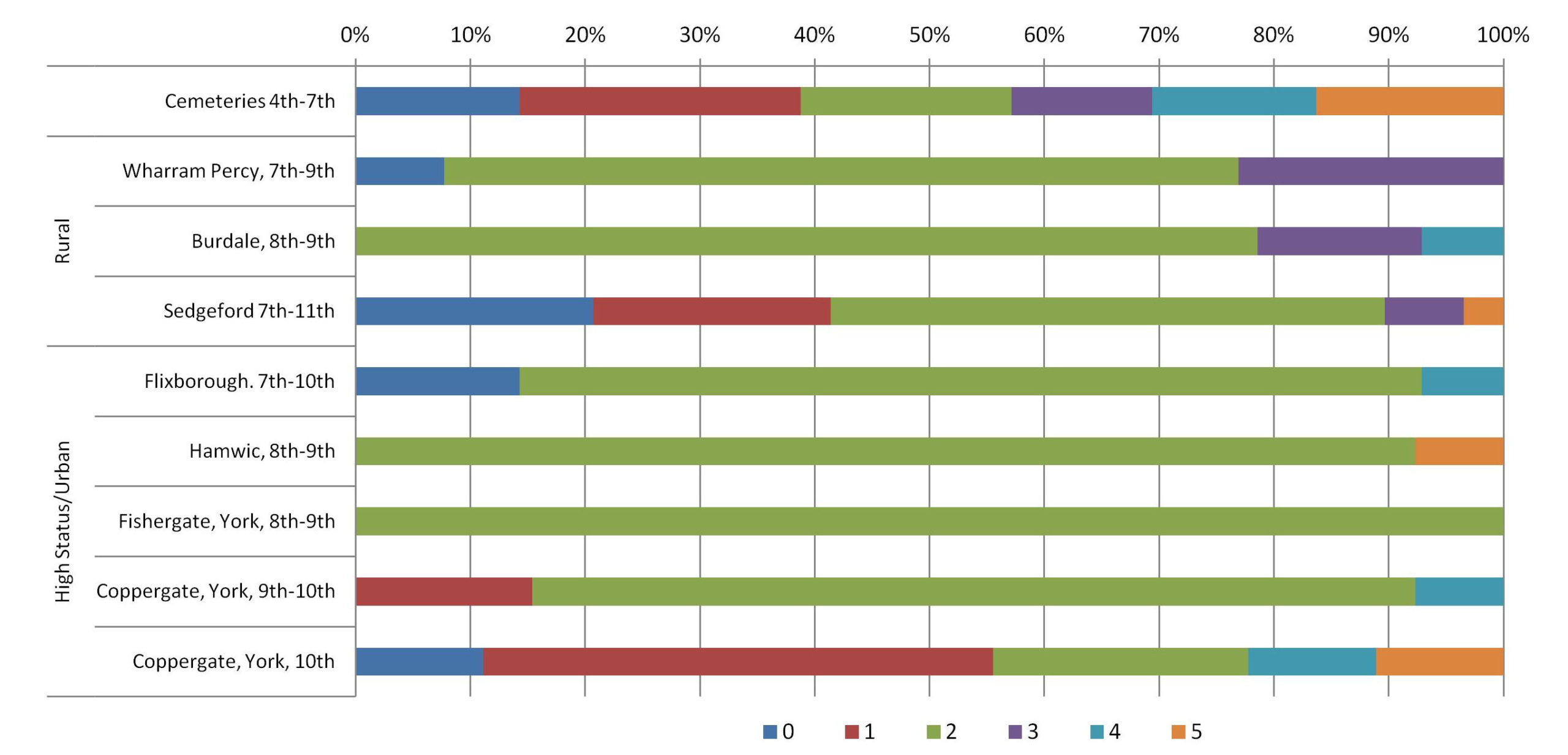

One possible reason for the difference between settlement and cemetery knives is that it reflects the differences between urban settlements, such as Hamwic and York, and rural cemeteries. So one aim of the PhD research was to determine whether the type of settlement site influenced the technology of knife manufacture, and the knife use. Knives from rural settlements were sought out to compare with those from contemporary urban settlements. To investigate this possibility knives from rural Wharram Percy and Burdale in Yorkshire and Sedgeford in Norfolk have been examined.

The examination of knives from rural settlements has shown that there is no difference in the way knives were manufactured in rural settlements when compared to urban sites, or even high status ecclesiastical settlements. This suggests that there was a standardised way of manufacturing knives in the middle to late Saxon period and this was not limited to the more ‘skilled’ urban blacksmiths. The type 2 knife makes the most economical use of steel which would have been more time consuming to manufacture, may have been scarcer and/or have travelled large distances. This in turn points to the technique being preferred for economic reasons rather than from a cultural view point.

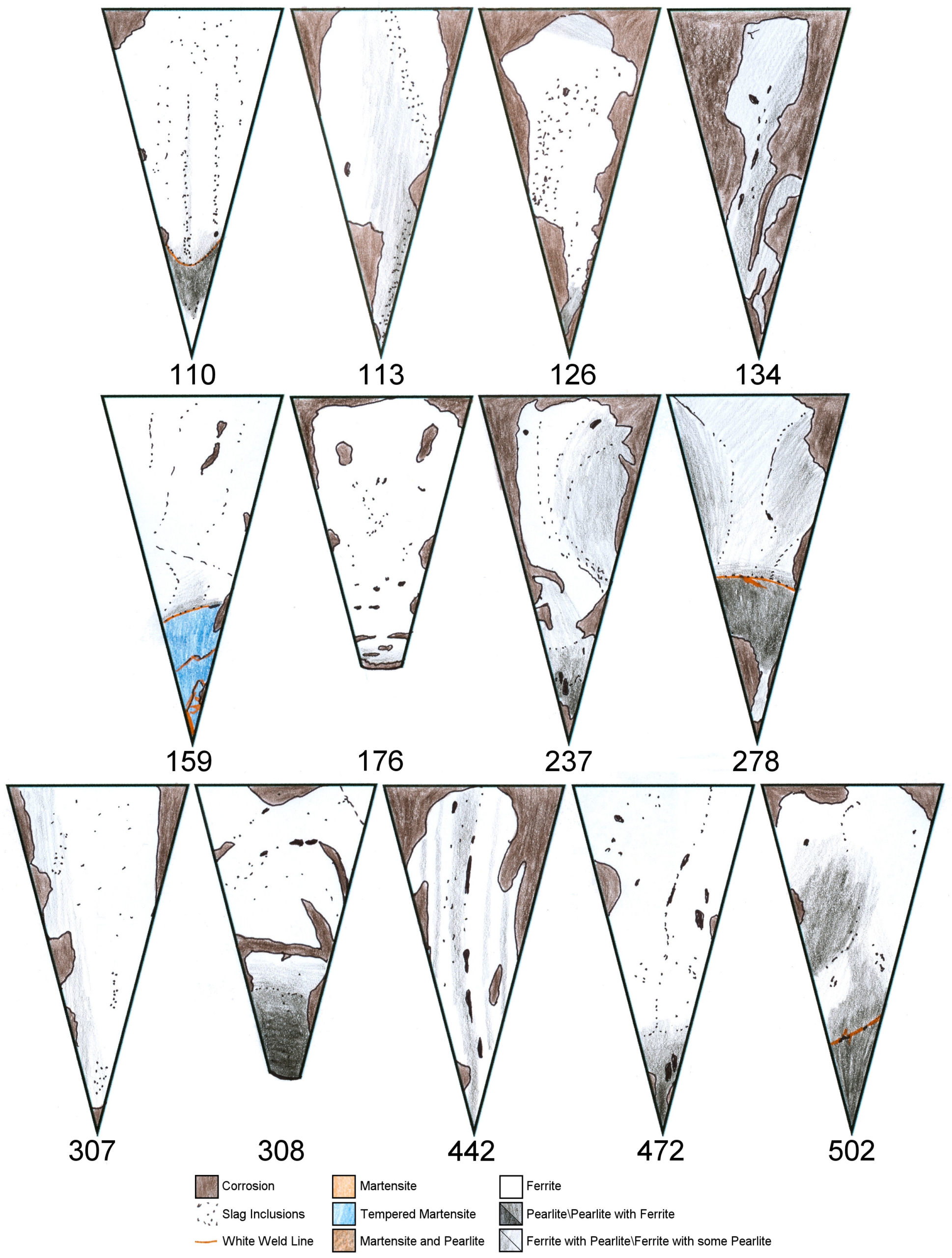

Figure 2a. Knives from Wharram Percy

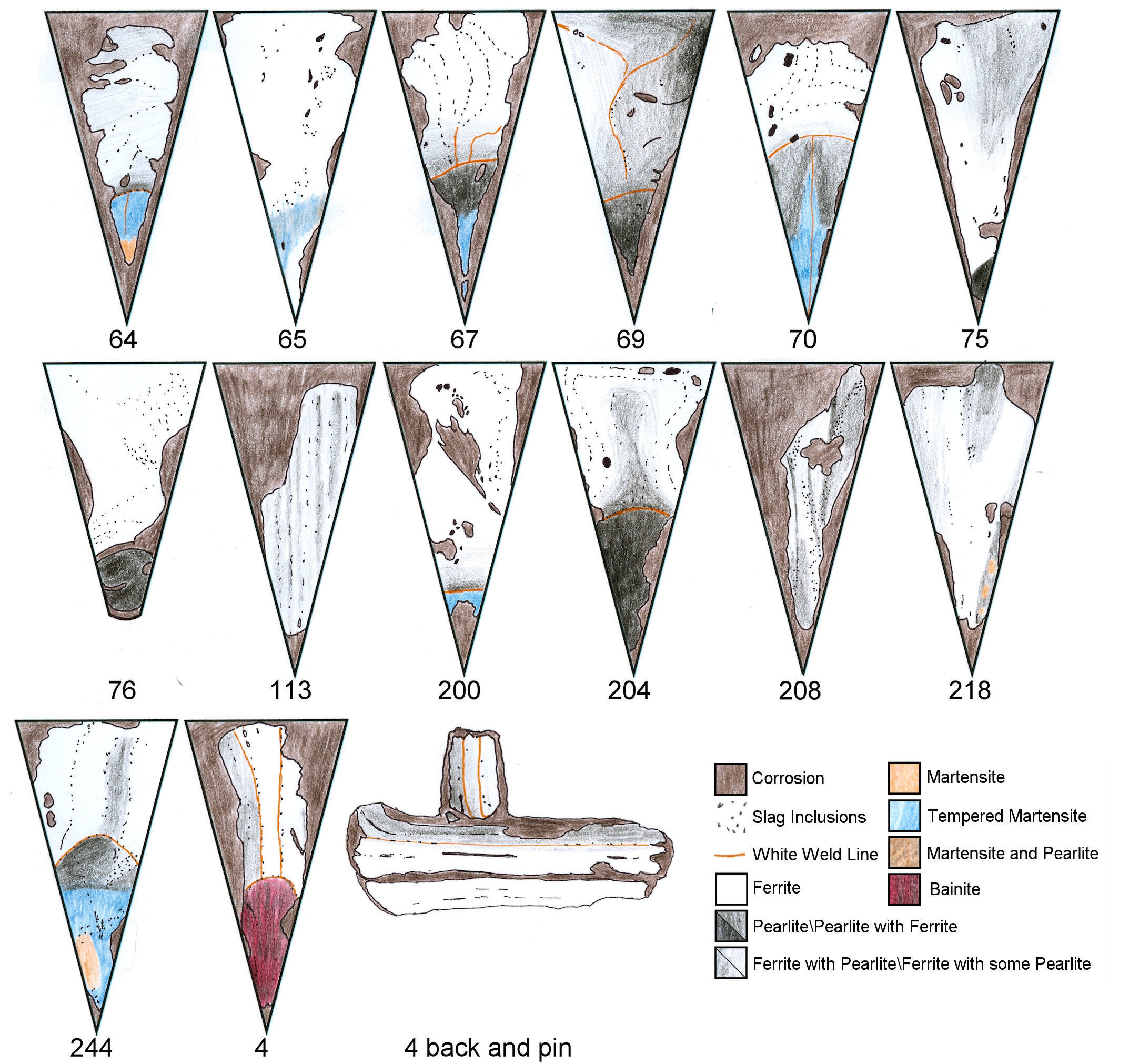

Figure 2b. Knives from Burdale

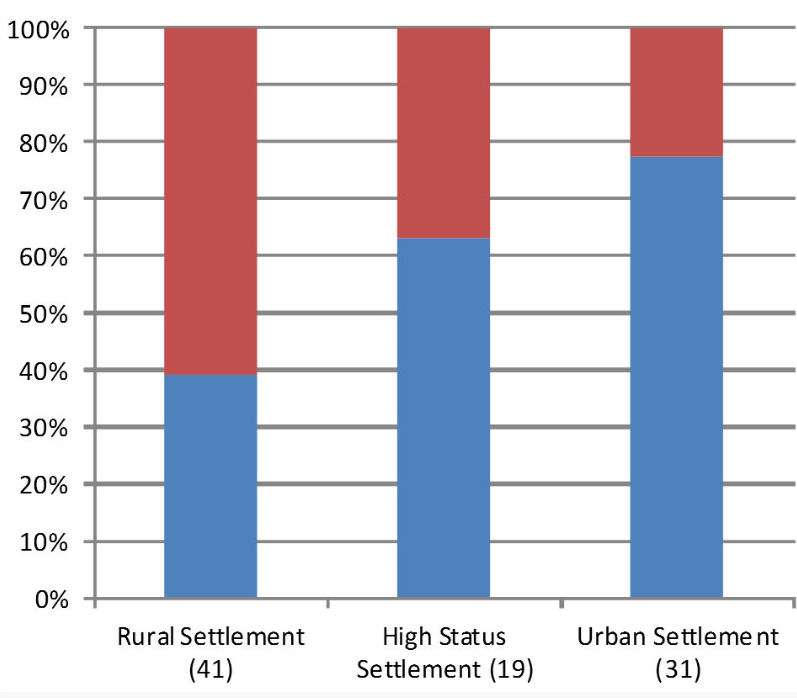

Instead, the biggest difference was the quality of the knives. Even though most iron alloys were available, many of the rural knives were not heat-treated to bring the best out of the steels used. Practically every settlement in the early medieval period had access to blacksmiths, as evidenced by the presence of smithing slag at most sites. But even within a smithy different skill levels are apparent, e.g. master vs apprentice. This study therefore points to a lack of what could be classed ‘master’ smiths in the rural settlements, with the knowledge of how to apply this final heat-treatment technique. There were also some dramatic differences in how the knives were repaired. In the urban settlements the repairs were done using high quality steels and heat-treatment techniques while the rural smiths had used poor quality iron to repair their knives, resulting in softer cutting edges. In addition a higher proportion of piled iron in the rural settlements suggested that recycling of iron was most likely taking place, whereas the urban settlements had access to better quality iron alloys.

Figure 3. Showing the differences between heat-treatments (red not treated while blue treated) in knives from rural Burdale and Wharram Percy compared to urban settlement knives.

References

- Blakelock, E. 2012. Cutting Edge of Technology: How the archaeometallurgical analysis of iron knives provides an understanding of the nature of iron technology in past societies. Archaeological Review from Cambridge 26(1): 66-84

- Blakelock, E.S. 2016. Metallographic examination of early medieval knives from the UK, Historical Metallurgy Journal 50(2): 85-94.

- Blakelock, E.S. and McDonnell, G. 2011. Early medieval knife manufacture in Britain: a comparison between rural and urban settlements (AD 400-1000). In Hošek, J., Cleere, H. and Mihok, L. (eds) The Archaeometallurgy of Iron: recent developments in archaeological and scientific research. Prague: Institute of Archaeology ASCR Prague. 123-136

- Blakelock, E. and McDonnell, G. 2007. A review of the metallographic analysis of Early Medieval knives. Historical Metallurgy 41(1): 40-56.

- McDonnell, G., Blakelock, E.S., Rubinson, S.R., Chabot, N., Daoust, A.B. and Castagnino, V. 2012. The iron economy of Saxon Wharram Percy: modelling the Saxon iron working landscape. In Wrathmell, S. (ed.) Wharram. A study of Settlement on the Yorkshire Wolds, XIII. A History of Wharram Percy and its Neighbours. York: York University Archaeological Publications.

- McDonnell, G. 1989. Iron and its alloys in the fifth to eleventh centuries AD in England. World Archaeology 20(3): 373-382.